Anchor Bolt

In construction projects, anchor bolts (roll bolts) are used to install metal plates of different sizes and thicknesses to the base material of hardened concrete, stone, brick, etc.

These plates provide the possibility of connecting and welding different metal parts to the concrete structure in order to implement various dry and composite facades, implement mechanical and electrical installation supports, install equipment and machines, etc. But what is important in this is choosing the right anchor bolt according to the type of performance, size, load capacity and installation limitations.

In terms of type and performance, bolt anchors are classified into two categories: mechanical and chemical.

In general, the performance of anchors (fixing in concrete or other materials) is done in four ways:

1- Friction or expansion

In this case, after installation or planting, the anchor can withstand different loads due to the friction force with the base materials. Most metal anchors – these types of anchors are also known as expansion anchors – and plastic (roll plates) work in this way and are easily installed.

2- Keying

In this case, the anchor causes a hold by creating holes or hoarding the base material – which in this case is often concrete. These types of anchors have a high load capacity and can withstand dynamic loads and can be installed at small distances from the edge of the base material.

3- Frictional and key combination (Combination of Friction & Expansion)

These types of anchors work in two frictional and key ways at the same time. These anchors also have a high load capacity and can withstand dynamic loads.

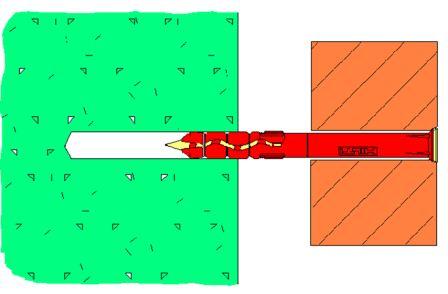

4- Bonding

Chemical anchors, which are also known as concrete glue or reinforcement planting glue, create load-bearing capacity by creating adhesion between the rebar or the rod with the base material. The advantage of using this type of anchors is the lack of restrictions on the diameter and depth of planting.

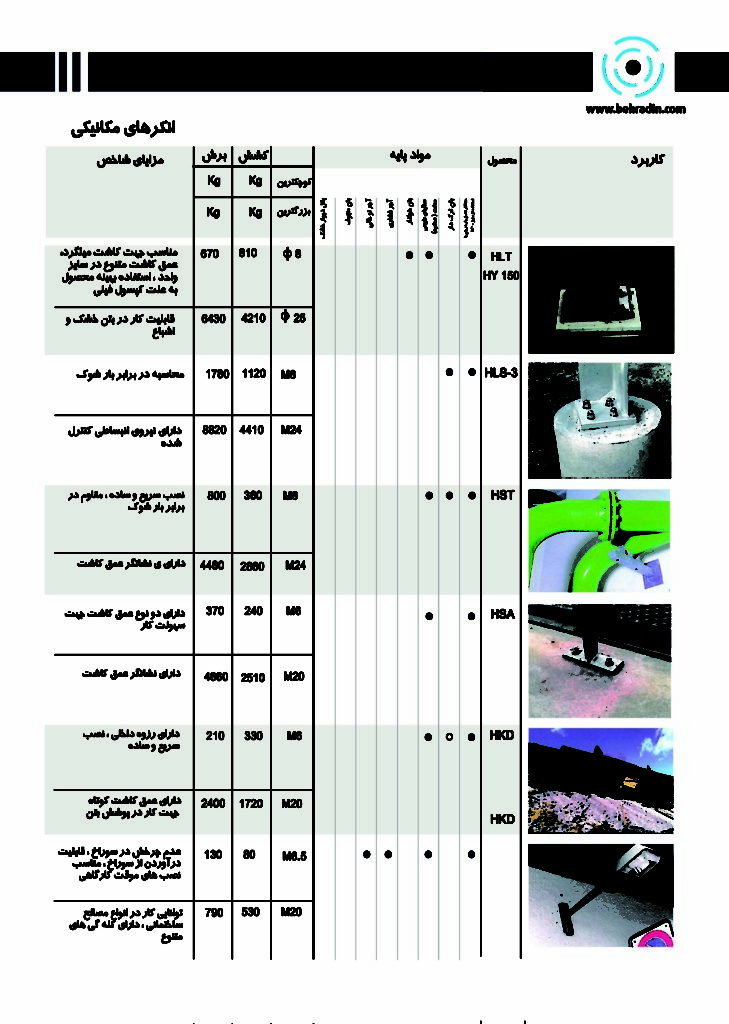

Mechanical anchors:

The effective factors in choosing the type of anchor are:

1- Environmental conditions

Geographical factors such as weather conditions and humidity levels, the presence of corrosive substances such as acids, fats, petroleum substances, phosphates, sulfates, etc. plants, power plants, factories, etc. are effective factors in choosing an anchor. The material (steel, plastic, and chemical) and coating (cold galvanized, hot galvanized, stainless steel, etc.) are selected anchors that are determined according to the environmental conditions.

2- Amount of load

Anchors can withstand different loads (between 10 and 15000 kg) depending on the need, type of function, material, type of load (tensile and shear or static and dynamic).

3- Type of load

In general, structural loads are divided into two categories:

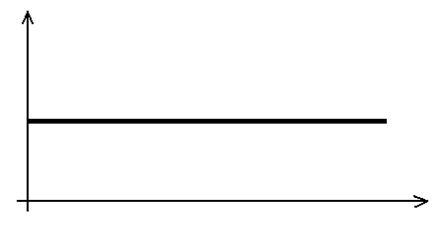

3-1 – Static loads (Static Load)

Static loads enter the structure at a constant rate and do not change over time. Dead load such as the weight of the structure, the weight of installed equipment, the weight of people, etc. are examples of static load. Almost all anchors can withstand this type of load.

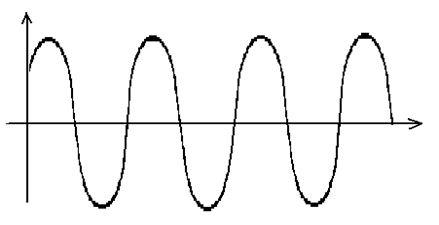

3-2 – Dynamic loads (Dynamic Load)

These types of loads change over time and are divided into three general categories:

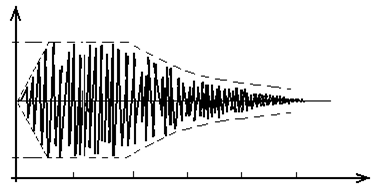

3-2-1 – Fatigue

The passage of people, machines, wind force, snowfall, all kinds of working devices and equipment such as electric motors are examples of creating these types of loads.

3-2-2 – Shock

This type of load is created in a very short time due to a strong collision, explosion or destruction of a part of the structure.

3-2-3 – Seismic

Obviously, in order to bear any type of dynamic load, the right anchor bolt must be selected.

4- Anchor bolt diameter and planting depth

Based on the amount of load as well as existing restrictions such as holes on the bases of machines and equipment that must be installed and other design and execution restrictions such as the distance of installing anchors from the edge of concrete or the distance of installing anchors from each other, diameter and The depth of anchor planting is determined.

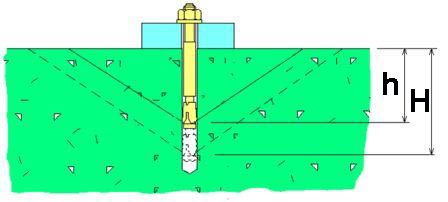

The depth of anchor planting will have a direct relationship with its load capacity, of course, the minimum and maximum of which depends on the thickness of the base material, as well as the capabilities of the manufacturer and the permission of existing regulations.

When the diameter of the anchor is certain and constant due to some mentioned restrictions, but its load is less than the amount of load, the anchor can be chosen by increasing the planting depth. On the other hand, if the anchor load is greater than the load, the planting depth can be reduced to make the best choice.

According to the above, chemical anchors are the only products that can be selected, designed and implemented with variable planting depth.

5- Base Material

Different types of concrete, including solid, hollow, light weight, cracked, aerated, etc., along with brick, hollow brick, Plaster and cement blocks (Gypsum & Cement Board), natural stones (Natural Stone) and… are among the materials that are one of the determining factors in choosing anchors due to their various resistances.

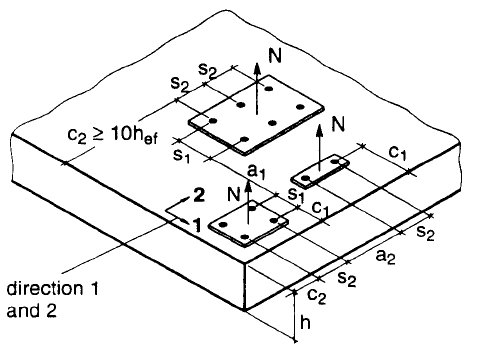

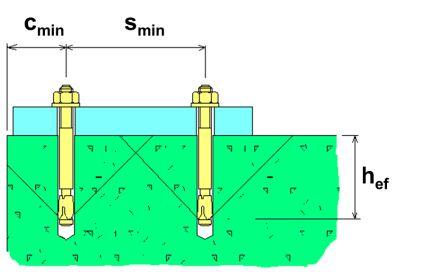

6- The distance from the edge of the base material and the distance between two anchors from each other (Edge & Space Distance)

Each type of anchor has specifications that require them to be installed at a certain distance from the free edge of the concrete, as well as at a certain distance from each other.

7- Implementation conditions

In general, anchors are installed in two ways:

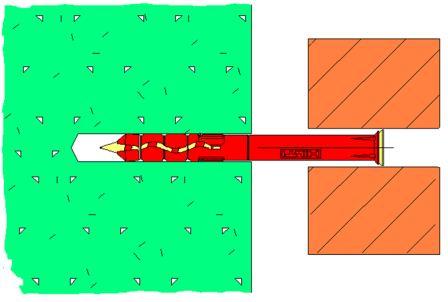

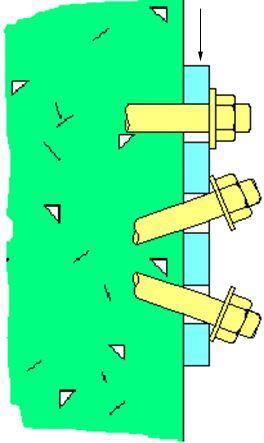

7-1 – Through Fastening

In the first method, bolt anchor and metal plate are installed simultaneously.

7-2 – Presetting

In this method, the anchor bolt is planted first, and then the metal plate, rod, armature, equipment, etc. are installed at the right time.

Types of Anchor Failure:

1- Pull Out

In this case, the anchor bolt is removed from the hole, without damaging the anchor bolt, metal plate and concrete.

Failure to comply with anchor installation specifications is the most important reason for this failure.

2- Pull over

The disproportion of the applied load with the thickness of the metal plate causes this failure. In this case, the metal plate is damaged.

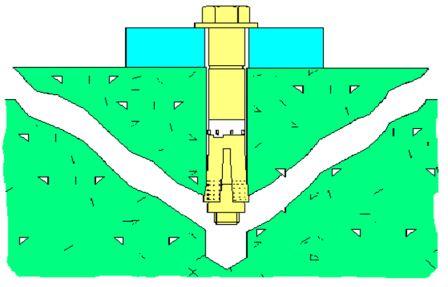

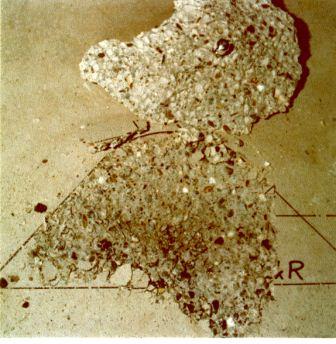

3- Concrete Breakage

When the anchor is installed in the concrete, the stresses are applied in a conical space in the concrete. If the concrete cannot withstand this amount of stress, concrete cone failure occurs.

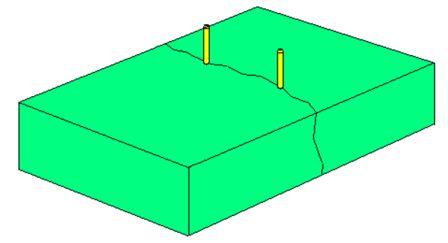

– Cracking of Base Material

This failure occurs when the minimum installation distance between two anchors or the minimum installation distance from the edge of the concrete is not observed.

5- Steel Breakage

In this case, the amount of load is greater than the tensile strength of the anchor and the anchor is so called cut.

Effective factors in anchor design:

In many cases, according to the conditions and the importance and sensitivity of the installation, the selection of the appropriate anchor should be done by design and based on some principles and related theories. Some effective factors in anchor design are:

1- In line with the load

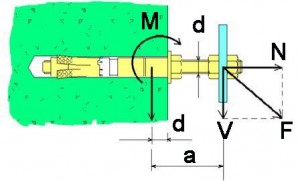

All incoming loads of any type and nature can be converted into two types of loads:

1-1 – Tensile Load (N)

1-2 – Shear Load (V)

For this reason, types of anchors are known with tensile and shear load capacity, and the amount of these loads must be known for anchor design.

2- Type of cargo

In static or dynamic design, the load must be determined.

3- Load on the structure

All the loads that enter the structure (and not the anchor) should be included in the design of the anchor. These loads can include the weight of structural members and equipment that are permanently installed (dead loads) or loads caused by wind, snow, earthquakes, or equipment and machinery in operation.

4- load on the anchor bolt (roll bolt)

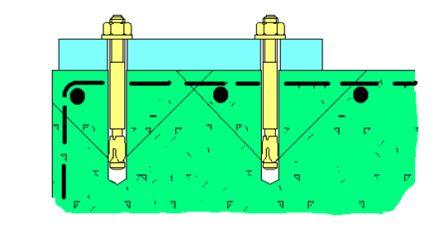

Due to the existence of some limitations such as improper installation of anchors, all of them may not bear the loads equally. As shown in the above pictures, in this case, only three anchors bear the applied shear load. To prevent this problem, the gap between the anchor and the hole between the metal plate can be filled with methods such as using special washers (Dynamic Set).

Obviously, the use or non-use of this method must be specified in the design.

5- Basic materials

6- The distance of the anchors from each other and the distance from the edge of the base material

As long as the stress cones formed by each anchor do not interfere with each other or are at a distance from the edge of the base material, the load of the anchors will not decrease, but in the conditions when these distances are reduced, it is necessary to apply reduction coefficients to the load of the anchors. be made

Obviously, these distances cannot be less than a certain amount.

7- Planting depth

A change in planting depth can change the size of the stress cone, which will have an effect on the design.

8- Concrete reinforcing bars

The presence of concrete reinforcing bars can help reduce the effect of stress cone interference.

9- Cracked concrete

When concrete as a base material is subjected to tension due to the application of force, small cracks are formed on it, which are often invisible to the eye and their size does not exceed 0.3 mm.

When anchors are installed in these areas and when the incoming loads are dynamic, the existence of these cracks reduce the anchor’s adhesion with concrete due to the opening and closing of the crack and cause the loss of the integrity of the formed stress cone. will be As a result, the load of the anchor will be between 30 and 35, which will affect the design of the anchor.

10- Anchor behavior in fire

When anchors are exposed to fire or explosion, their load capacity decreases over time. Therefore, the existence of information related to their behavior and load reduction has a direct effect on the design.

Design regulations:

Anchor design is done based on civil regulations. Before choosing the regulations, it is necessary to determine the purpose of the design, which is divided into two parts:

Installation of metal plate and rebar planting

ICBO, ACI, SOCOTEC, Dibt, ETA are among these regulations, ETA (Europe) and ACI (America) are among the most reliable.

ETAG : Europian Technical Approval Guidline

ETAG 001 Annex C

Mechanical

Standard Layout

Standard Embedment Depth

ETAG 020

Plastic Anchors

EOTA TR 029

Design of Bonded Anchors

ETAG Fire : Based on EOTA TR 020

Evaluation of Anchorages in Concrete Resistance to Fire

ICC : Design Method Using the Provision of ACI 318-05 and ICC-ES AC 193 and AC 308

Chemical anchor or concrete glue (Chemical Anchor):

Failure to properly implement reinforcement, changing structure plans, adding new, resistant parts, and continuing concreting operations in cases where the installation of rebar is forgotten or not foreseen, is one of the common cases in the implementation of concrete structures and is one of the The best and least expensive solution to fix the above mentioned problems is to install rebar with chemical anchors or concrete adhesives. Likewise, metal plates can be installed on the surface of concrete by installing threaded rebar.

Rebar planting operations include drilling holes with specific diameter and depth in concrete, injecting chemicals into the hole and placing rebars. Due to the sensitivity and importance of the issue, this company performs all the necessary work, including designing with specialized software, consulting and providing a full report. It takes over the technical and implementation of planting completely.

Applications of anchor bolt (roll bolt):

Installation of all kinds of partitions, false ceiling, building sanitary equipment, hospital equipment, prefabricated concrete panels, building metal facade, elevator and escalator rails, metal scaffolding, supports and holders for piping and channeling systems, equipment and machines Instruments, railroad and subway lines, overhead cranes, port equipment, airplane hangars, electrical and telecommunication masts, etc., are examples of the use of this product.

Anchors can be provided in reputable brands such as HILTI, Fischer, Spit and other miscellaneous brands.

This company, with special experience and expertise in designing all kinds of anchor bolts using specialized and advanced software and an experienced engineering team, is ready to provide technical advice and engineering services and necessary calculations in order to choose the right product, free of charge for all projects. construction and industrial.